Solutions

Solutions

Cold plate liquid cooling solution

Solution Brief

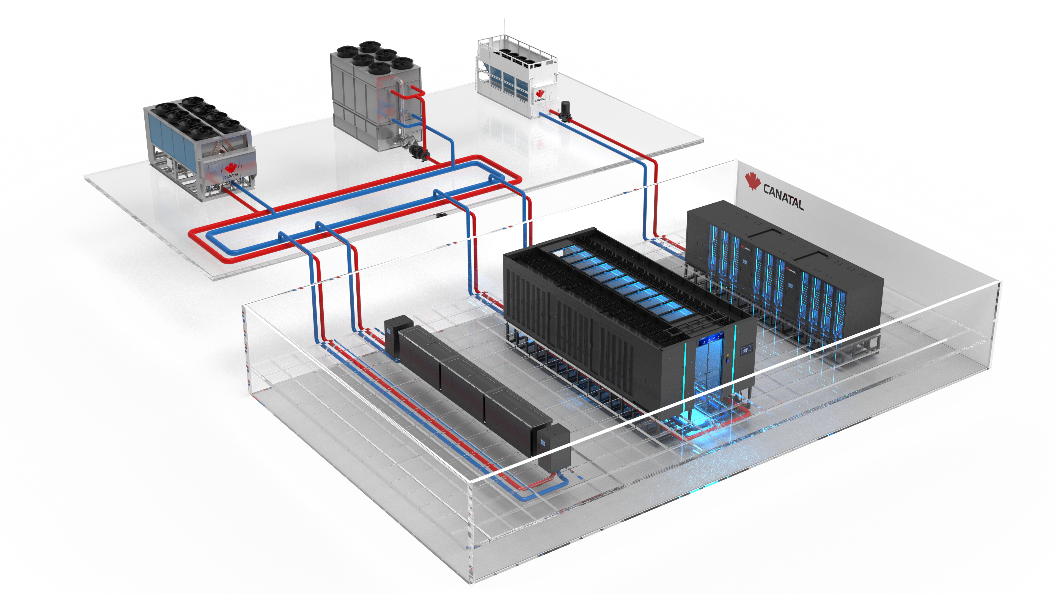

Cold plate liquid cooling indirectly transfers heat from heat-generating components to a cooling liquid enclosed in a circulating pipeline through a cold plate (usually a closed cavity made of heat-conducting metals such as copper and aluminum). The cooling liquid transfers the heat to the heat exchanger CDU through the pipeline, and then the CDU conducts the heat to the primary side to be discharged outdoors. The cold plate liquid cooling system consists of two parts: the primary side and the secondary side. The primary side includes: cooling tower and hydraulic system (water pump, pipeline), etc. The secondary side includes: CDU, liquid-cooled cabinet, coolant pipeline, etc.

Suitable for data center construction scenarios with high single-cabinet power density, high load, and high requirements for PUE and energy saving and emission reduction; this scheme also belongs to indirect liquid cooling technology, liquid cooling can take away 60~80% of the heat in IT equipment, the remaining 20~40% still needs to be taken away by air cooling, and needs to be used with traditional air-cooled data center air conditioners. It can be applied to energy-saving renovation scenarios where the original air-conditioning water system can be utilized and the original air-cooled data center air conditioners are not completely removed.

Key Parameters

CDU parameters 20kW, 30kW, 300kW, 600kW, 900kW

Applicable Scenarios

High-power density data centers, operators, government, education, medical, finance, internet IDC, enterprises.

Advantageous Features

▪ Pre-fabricated, highly compatible: The system composition is relatively simple. The key to scheme implementation lies in the performance of three products: heat exchange CDU, liquid cooling plate, and coolant distribution unit manifold. The factory prefabrication degree is high, ensuring data center quality is not affected by construction quality, and the construction period is short;

▪ High performance: Can meet the demands of ultra-high power density IT equipment usage scenarios, with single cabinet power density up to 60kW or more;

▪ Low noise: The coolant circulation noise in the liquid cooling plate heat dissipation part is extremely low, and at the same time, the fan speed in the air cooling part is reduced, decreasing noise. Full load operating noise is no more than 60dB;

▪ High cooling efficiency, low energy consumption, low TCO: In a 25℃ inlet water environment, with 100% CPU operation, the energy saving rate is 9.6% relative to ordinary server IT equipment, and 84% for air conditioning equipment.

Address: No. 88, Suyuan Avenue, Jiangning Economic and Technological Development Zone, Nanjing

Tel:+86-025-84916609

Mobile:+8618061637872

Postcode: 211111

E-mail: trade@canatal.com.cn

Jialitu Machine

Copyright @ 2025 Nanjing Canatal Data-Centre Environmental Tech Co.,Ltd